Rail Temperature isn’t just a Number; it’s a Lifesaver!

February 1, 2025

Railways, too, got its own winter and summer care! Only that moisturizers and sunscreens are not the solution here.

Let’s see what PIE got to say for track summer and winter maintenance.

Maintaining railway lines is a difficult task when temperatures drop to chilling lows or soar to scorching highs. Dangerous breakage and derailments may result from steel rails contracting or expanding due to extreme weather conditions.

Take Chicago, by way of example, where brutal winters (we’re talking freezing cold, even penguins are wearing jackets!) push maintenance crews to light up the tracks. Yeah, you read that right, they literally set the rails on fire using gas-fed heaters to prevent them from contracting and pulling apart. What might seem like an extreme solution is, in fact, a century old, effective method for keeping rail operations safe and smooth.

But what if there was a more precise, less dramatic way to track temperature fluctuations? That’s where PIE’s rail temperature monitoring solutions step in.

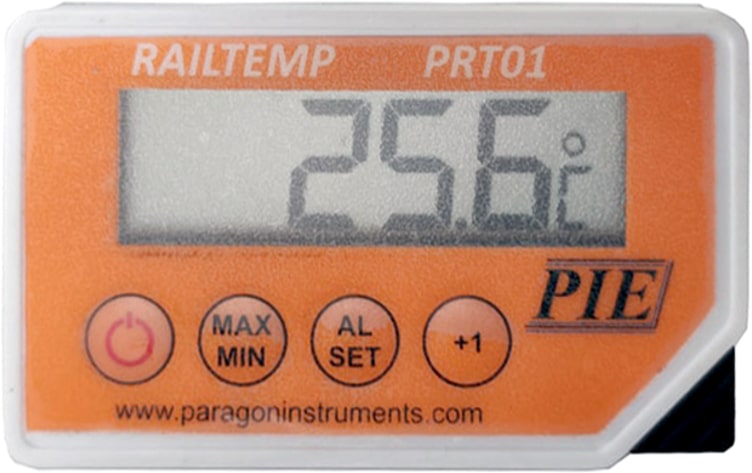

Stay on Track with PIE’s Digital Rail Temperature Measuring Device PRT-01

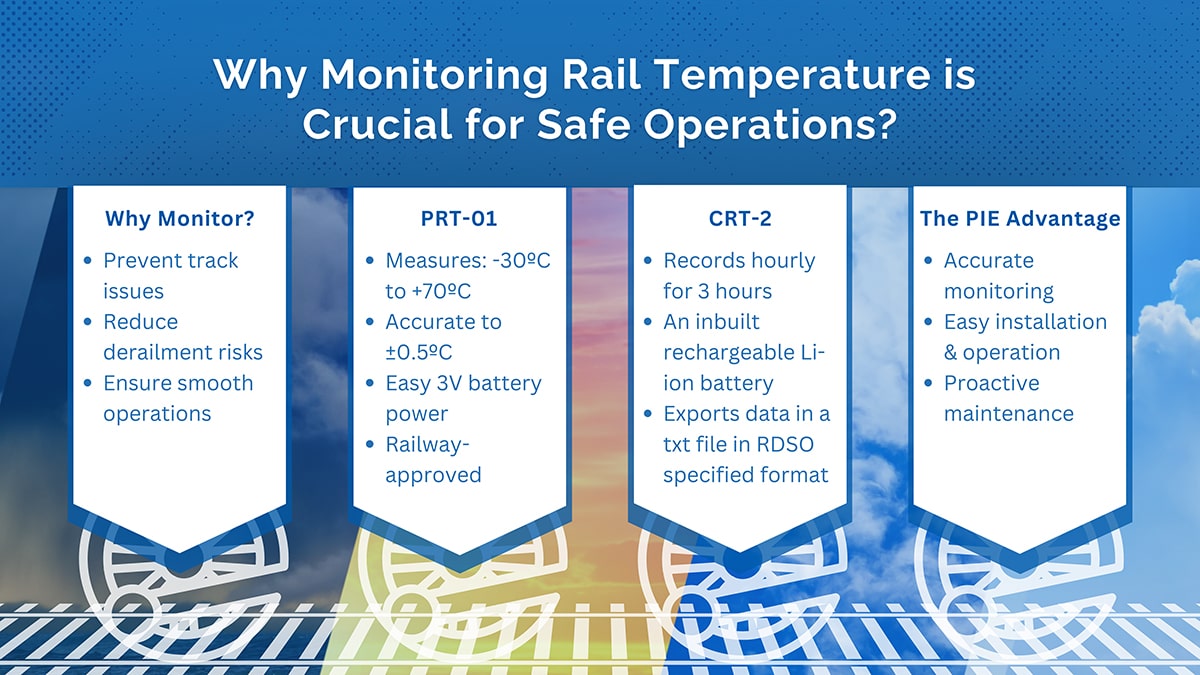

The PIE Make Digital Rail Temperature Measuring Device Model PRT-01 is a game changer for railway track teams. Designed to be placed directly on the rail web railway’s recommended practice this device provides accurate, real time temperature readings with a range from -30ºC to +70ºC. With an impressive accuracy of +0.5ºC in the most critical range and the ability to store maximum and minimum readings, it ensures no data is missed. The compact 3-digit LCD display and simple CR2032 battery make it an essential tool for quick, reliable checks.

Long-Term Monitoring with PIE’s Continuous Rail Thermometer CRT-2

For those who need long term insights, the PIE Brand Continuous Rail Thermometer Model CRT-2 offers a robust solution. Recording temperature data hourly for up to 3 years, this device helps track teams analyze trends and make data driven decisions. It consists of a recorder with an enclosure, a sensor with a 45m cable, a pen drive for data export, a 12V charger, and an instruction manual. The thermometer features a 16×2 alphanumeric display, an inbuilt rechargeable Li-ion battery pack, and a 12V charger with a 6 hour charging time. Once fully charged, it can run for 4 days. Additionally, it provides maximum and minimum temperature alerts and exports data in a text file format specified by RDSO, ensuring seamless compatibility with any PC having a USB port.

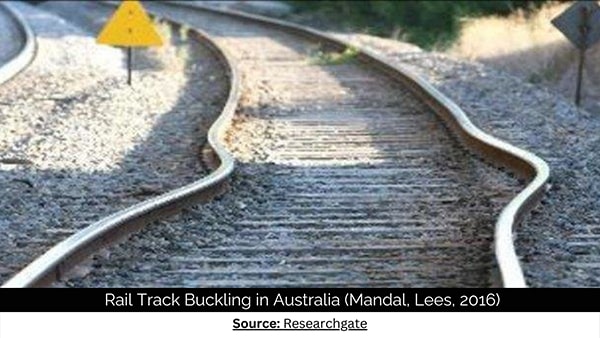

In contrast to methods used in places like Russia and Canada, where electric track heating systems and hot-air blowers keep snow and ice at bay, India’s soaring summer temperatures present a different challenge. Meanwhile, in India, the heat expands the rails, and without proper adjustments, can lead to track misalignment and accidents. To tackle this, the Indian Railway teams use a technique called “destressing,” where tracks are adjusted to their “neutral temperature” to prevent dangerous buckling.

| Factor | Winter Contraction | Summer Expansion |

|---|---|---|

| Cause | Extreme cold temperatures | High ambient temperatures |

| Effect on Rails | Contraction, leading to gaps and fractures | Expansion, causing track misalignment |

| Common Issues | Rail breaks, increased tension | Buckling, warping, and misalignment |

| Preventive Measures | Gas-fed heaters, track heating systems | Destressing, rail neutral adjustments |

| Example Locations | Chicago, Russia, Canada | India, Australia, Middle East |

| Device Type | PRT-01 | CRT-2 |

|---|---|---|

| Temperature Range | -30ºC to +70ºC | -5ºC to +85ºC |

| Accuracy | ±0.5ºC in critical range | ±1ºC |

| Display | 3-digit LCD | 16×2 Alphanumeric Display |

| Power Source | CR2032 battery | Inbuilt rechargeable Li-ion battery pack |

| Ideal Use | Quick checks during maintenance | Long-term monitoring and analysis |

Why Rail Temperature Monitoring Matters

Whether facing extreme cold or intense heat, rail temperature monitoring is vital. Expansion during high temperatures can cause tracks to buckle, while contraction in freezing weather can lead to cracks. With PIE’s PRT-01 and CRT-2, track maintenance teams can stay ahead of these risks, ensuring operational safety and efficiency.

With PIE, the trains are always on track and on time, every time.

The PIE Advantage: Practical, Accurate, and Reliable

Whether you need instant readings with the PRT-01 or long term data tracking with the CRT-2, PIE’s solutions provide practical, easy-to-use tools that help teams optimize maintenance schedules and ensure smooth railway operations. With features like USB connectivity, non-volatile memory storage, and easy deployment kits, PIE’s instruments take the guesswork out of rail monitoring.

Know more about our rail thermometers here

From Chicago’s fiery rails to India’s summer proof tracks, the world’s railways face unique challenges but with PIE’s technology, staying on track has never been easier. So, the next time the mercury rises or plunges, you’ll know exactly what’s happening beneath those wheels all because you got Paragon Instrumentation’s precision.