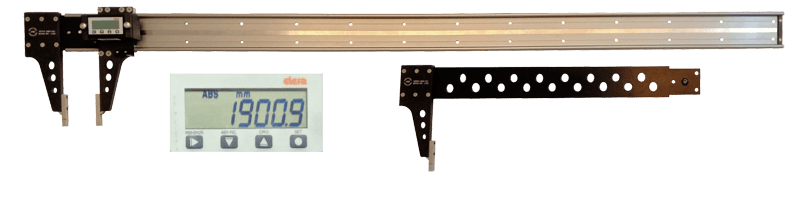

The ABT 4640 allows the user to take height and stagger measurement of the OHL (Over-Head Line)/Railway Catenary using a Measurement Laser.

The laser is positioned at Eye Level and features a 90 viewing prism, enabling the operator to see the desired cable and laser location marker at the same time in all weather conditions including bright sunshine. The rail Head to Cable Height is displayed on an LCD display, the value is compensated for the Height offset of the laser, meaning that no onsite calculation is required.

Cable stagger position is indicated on a scale on the lateral beam of the gauge. The horizontal beam folds down flat to the lateral beam for storage and transport.

The Gauge is available for B.G and S.G. Available in metal and fibre variants.

TECHNICAL SPECIFICATIONS: –

| Sl | Parameter | FOR B.G (1676 mm) | For S.G (1435 mm) |

| 1 | Weight | 8.2 Kg | 7.8 Kg |

| 2 | Size | 1845mmX1620mmX265mm | 1450mmX1620mmX265mm |

| 3 | Cant | Range: ±199mm Accuracy: ± 1mm Resolution: ± 0.1mm Expected battery life 12month | Range: ± 199 mm Accuracy: ± 1 mm Resolution: ± 0.1 mm Expected battery life 12 months |

| 4 | Cable Stagger | Range: 520 mm Accuracy: ± 10mm @ 5m Resolution: ± 0.1mm | Range: ± 520 mm Accuracy: ± 10mm @ 5m Resolution: ± 0.1mm |

| 5 | Cable Height | Range: 2m – 100m Accuracy: ± 3mm Resolution: ± 0.1mm | Range: ± 2m – 100m Accuracy: ± 3.0mm Resolution: ± 0.1mm |

| 6 | REFOS- Range | Range: ± 2m to 100m Accuracy ± 3.0 mm Resolution ± 0.1mm | Range: ± 2m to 100m Accuracy ± 3.0 mm Resolution ± 0.1mm |