‘PIE’ make Trammelling Gauge suitable for Casnub Bogies fitted with Vernier scale. Measuring Range: 1900 mm to 2000 mm, 2100 to 2200 mm & 3000 mm to 3100 mm. Accuracy: ±1.0 mm. Material High Grade Aluminium (6063T6), tube-size 50 mm Sq. Stainless Steel scale with hardened pointer. Supplied in light weight, nicely finished wooden storing & transportation box.

Railway Measurement

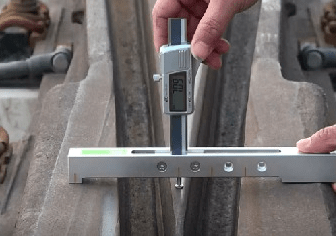

Digital Switch Rail Vertical Wear Measuring Gauge Model PSWG-1

‘PIE’ make Digital Switch Rail Vertical Wear Measuring Gauge Model PSWG-1 used to measure switch rail/point rail/check rail reduction relative to the basic rail and the point rail reduction relative to the wing rail. The gauge is supplied in carrying case with zero setting device.

MAIN SPECIFICATIONS: –

| Resolution | 0.01 mm |

| Accuracy | ± 0.05 mm |

| Range | Up to 25 mm |

| Display | LCD |

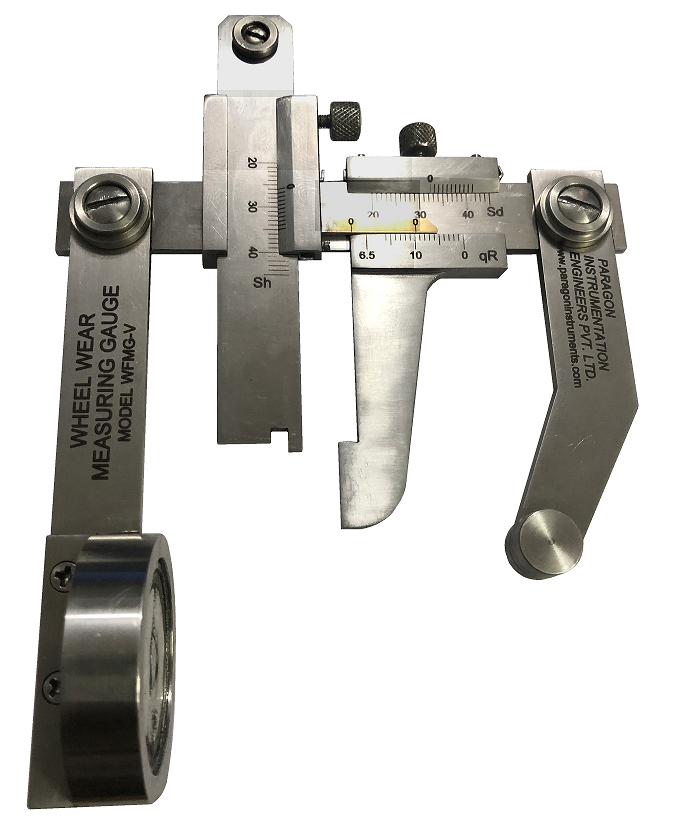

Multipurpose Wheel Wear Measuring Gauge/qR Gauge Model WWMG-V

‘PIE’ brand Multipurpose Wheel Wear Gauge/qR Gauge our Model WWMG-V fitted with magnet for easy mounting on flange. Made of stainless steel with Least Count of 0.1 mm. Suitable for measuring flange thickness, flange height and value of qR of flange with following measuring ranges.

- Flange Thickness ‘Sd’ 20 mm to 50 mm

- Flange Height ‘Sh’ 20 mm to 50 mm

- Flange qR Value – 0 to 20 mm.

The Gauge is supplied in well finished case. The measuring point is 70 mm from back of flange.

ELECTRONIC TRACK GAUGE MODEL AL-6 (E)

‘PIE’ make Electronic Track and Turnout Gauge Model AL-6 (E) for Broad Gauge (1676 mm) are made of extruded aluminium section, capable of measuring Track Gauge, Super Elevation (Cant), Check Rail Gauge, Back to Back Distance & Flange way Clearance precisely by means of an easy to read digital Display system and supplied in a padded carrying bag.

Special features of the gauge: –

- The gauge has an inbuilt memory to save up to 50 measurements.

- The Display can be rotated through 180º for case in use from both sides of the gauge.

- Digital easy to read OLED Display.

- Light weight, robust & durable aluminium construction.

- Insulated construction.

SPECIFICATIONS: –

| Parameter | Measuring Range | Overall Accuracy |

| Cant | ± 200 mm | ± 0.5 mm |

| Track Gauge | 1651 mm – 1731 mm | ± 0.2 mm |

| Check Rail Gauge | 1633 mm – 1713 mm | ± 0.2 mm |

| Back-to-Back Distance | 1615 mm – 1695 mm | ± 0.2 mm |

| Flange Way Clearance | 20 mm – 100 mm | ± 0.2 mm |

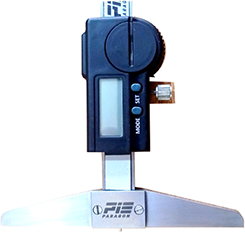

DIGITAL CORROSSION MEASURING GAUGE MODEL – PCMG-2

‘PIE’ brand Digital Corrosion Measuring Gauge Model PCMG-2 is used for measuring the depth of cavity developed due to corrosion of rails. The reading is displayed directly on LCD display and is provided with hardened steel pointer.

SPECIFICATIONS: –

- Measuring Accuracy: ± 0.01 MM.

- Measuring Depth of small groove and hole.

- Resolution: 0.01mm/0.0005”

- Measuring reference base: 65 MM X 7 MM

- Buttons: On/Off, set, mm/inch, present (+, -)

- Automatic power off, move the digital unit to turn on power.

- Battery: CR2032

- Data Output (Optional)

NOTE: –THE GAUGE WILL BE SUPPLIED WITH ‘PIE’ CALIBRATION CERTIFICATE TRACEABLE TO NATIONAL STANDARD/NPL STANDARD NOT OF ANY OTHER AGENCY. OUR MASTERS ARE CALIBRATED BY NABL APPROVED LABS.

PORTABLE TRACK GAUGE CALIBRATION BENCH

‘PIE’ brand Portable Track Gauge Calibration Bench made of steel extruded tubing provided with hardened steel testing fixtures set at defined track gauge useful for onsite checking and calibration of Track Gauges Calibrated for Broad Gauge 1676 mm/Standard Gauge 1435 mm (as per user requirement).

The Track Gauge is supplied complete in transportation and storing box with working manual and Recalibration device.

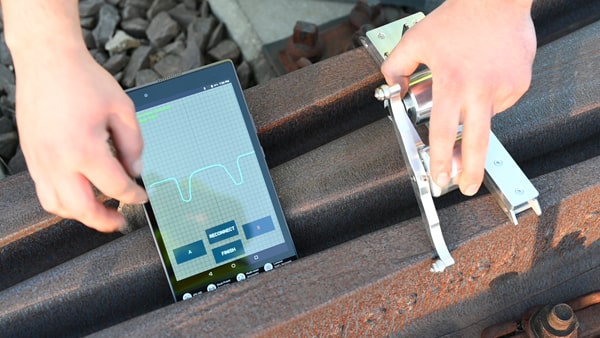

Rail Profile Gauge Cum Recorder – Model RPCS Basic 2.0 with Frog (Point) Measurement attachment.

Rail Profile Gauge Cum Recorder – with Frog (Point) Measurement attachment along with ruggedized Android Tablet.

The application fields of RPCS: –

- Checking the manufactured rail profile at takeover.

- Periodic checking the rail wear for planning the maintenance.

- Measuring the eliminated material and measuring the profile during grinding activity (FWB Machine).

The portable RPCS is a very effective equipment for measuring the rail profile because of its light weight, simple and quick operability. The magnetic measuring base and the telescopic support leg provide the stability of the adequate measuring position. The mechanical scanning roller scans the real rail profile, therefore the contamination on the rail surface does not distort the measurement. The profile measurement can be done on most of the rail types e.g. on Vignol and Phoenix rails as well. The double measuring bar provides the possibility to measure the rails with extreme wear, rails with crinkling and the inclination of the rail can be calculated by measuring the bottom surface of the rail head. The geometric preparation of the bar was done by taking into consideration ergonomic examinations in order to decrease the number of the unnecessary move of the hands.

The handheld computer connects to the RPCS via Bluetooth connection. Shock and resistant and water transport box provide the safe transportation of the device and its accessories. The changeable battery ensures the continuous operation over several shifts.

The functions of the measuring program: –

- Recording the identification data of the measurement.

- The instant display of the measuring results.

- Calculation of wear features from the measured profile.

- Comparison of two measurements.

- Numeric display of differences.

With a “Frog” attachment the RPCS device is capable of measuring the cross-section profile of the frogs at turnouts.

The following parameters can be measured and calculated with this option:

- The height wear of the switch blade.

- The width of the flangeway

- The depth of the flangeway

Technical Specification: –

| Resolution | 5 µm |

| Accuracy in lab (polished rail w/o rust & dust) | ±0.01 mm |

| Accuracy | ±20 µm |

| Repeatability | ±10 µm |

| Time demand of one measurement | cc. 8 seconds |

| Measuring range X | 320 mm |

| Measuring range Y | 60 mm |

| Operating temperature | -20°C… +55ºC |

| Supply | 1 X Li-ion rechargeable battery (18650 type) |

| Operating time | Min. 8 hours / 1000 measurements |

| Insulation resistance | 2 Mohm/500 V (DC) |

| Dust and water resistance | IP54 |

| Communication way | Bluetooth |

| Dimensions | 125x150x150mm |

| Overall system weight | ˂ 8 Kgs |

Rail Profile Gauge Cum Recorder – Basic Version Model RPCS Basic 2.0

Rail Profile Gauge Cum Recorder – Basic Version Model RPCS Basic 2.0 along with ruggedized Android Tablet.

The application fields of RPCS: –

- Checking the manufactured rail profile at takeover.

- Periodic checking the rail wear for planning the maintenance.

- Measuring the eliminated material and measuring the profile during grinding activity (FWB Machine).

The portable RPCS is a very effective equipment for measuring the rail profile because of its light weight, simple and quick operability. The magnetic measuring base and the telescopic support leg provide the stability of the adequate measuring position. The mechanical scanning roller scans the real rail profile, therefore the contamination on the rail surface does not distort the measurement. The profile measurement can be done on most of the rail types e.g. on Vignol and Phoenix rails as well. The double measuring bar provides the possibility to measure the rails with extreme wear, rails with crinkling and the inclination of the rail can be calculated by measuring the bottom surface of the rail head. The geometric preparation of the bar was done by taking into consideration ergonomic examinations in order to decrease the number of the unnecessary move of the hands.

The handheld computer connects to the RPCS via Bluetooth connection. Shock and resistant and water transport box provide the safe transportation of the device and its accessories. The changeable battery ensures the continuous operation over several shifts.

The functions of the measuring program: –

- Recording the identification data of the measurement.

- The instant display of the measuring results.

- Calculation of wear features from the measured profile.

- Comparison of two measurements.

- Numeric display of differences.

Technical Specification: –

| Resolution | 5 µm |

| Accuracy in lab (polished rail w/o rust & dust) | ±0.01 mm |

| Accuracy in field | ±15 µm |

| Repeatability | ±10 µm |

| Time demand of one measurement | cc. 4 seconds |

| Operating temperature | -20°C… +55ºC |

| Supply | 1 X Li-ion rechargeable battery (18650 type) |

| Operating time | Min. 8 hours / 1000 measurements |

| Insulation resistance | 2 Mohm/500 V (DC) |

| Dust and water resistance | IP54 |

| Communication way | Bluetooth |

| Dimensions | 125x150x150mm |

| Overall system weight | ˂ 7 Kgs |

LASER HEIGHT & STAGGER GAUGE MODEL ABT4640

The ABT 4640 allows the user to take height and stagger measurement of the OHL (Over-Head Line)/Railway Catenary using a Measurement Laser.

The laser is positioned at Eye Level and features a 90 viewing prism, enabling the operator to see the desired cable and laser location marker at the same time in all weather conditions including bright sunshine. The rail Head to Cable Height is displayed on an LCD display, the value is compensated for the Height offset of the laser, meaning that no onsite calculation is required.

Cable stagger position is indicated on a scale on the lateral beam of the gauge. The horizontal beam folds down flat to the lateral beam for storage and transport.

The Gauge is available for B.G and S.G. Available in metal and fibre variants.

TECHNICAL SPECIFICATIONS: –

| Sl | Parameter | FOR B.G (1676 mm) | For S.G (1435 mm) |

| 1 | Weight | 8.2 Kg | 7.8 Kg |

| 2 | Size | 1845mmX1620mmX265mm | 1450mmX1620mmX265mm |

| 3 | Cant | Range: ±199mm Accuracy: ± 1mm Resolution: ± 0.1mm Expected battery life 12month | Range: ± 199 mm Accuracy: ± 1 mm Resolution: ± 0.1 mm Expected battery life 12 months |

| 4 | Cable Stagger | Range: 520 mm Accuracy: ± 10mm @ 5m Resolution: ± 0.1mm | Range: ± 520 mm Accuracy: ± 10mm @ 5m Resolution: ± 0.1mm |

| 5 | Cable Height | Range: 2m – 100m Accuracy: ± 3mm Resolution: ± 0.1mm | Range: ± 2m – 100m Accuracy: ± 3.0mm Resolution: ± 0.1mm |

| 6 | REFOS- Range | Range: ± 2m to 100m Accuracy ± 3.0 mm Resolution ± 0.1mm | Range: ± 2m to 100m Accuracy ± 3.0 mm Resolution ± 0.1mm |

AIR SPRING HEIGHT MEASURING GAUGE

‘PIE’ make Set of two Air Spring Height Measuring Gauges (GO & NO GO), generally & functionally as per Drawing no. SK/GAUGE – 1/2021. The gauge is made from hard steel/hardened stainless steel and each gauge is supplied in a wooden box. Each set consist of one GO-Gauge and one NO-GO Gauge